Description

Application Field

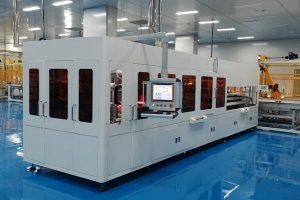

This equipment is used to automatically weld solar cells with 5,6,9,10,11,12 to 20 grid lines in series according to the set parameters into a solar stringer.

Teflon conveyor belt transmission mechanism;Flux circulation immersion supply.

Automatic film supply positioning and tape pulling.

Adopting infrared welding method.

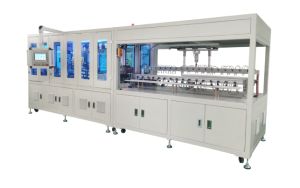

| Model | AZCH-1800 |

| Basic information | |

| Soldering speed | 1400-1500P/Hour |

| Breakage ratio | ≤2‰(Based on A grade cells without secondary sorting) |

| Contact error | ≤0.2mm(Based on A grade cells without secondary sorting) |

| Operation control | PLC |

| Soldering way | IR |

| Basket qty | 4Pieces(recommend 100P cell/pieces) |

| Aligning control | Ribbon conveyor&Welding mechanism calibration |

| Cell parameter | |

| Applicable Cells | 26~156*156mm;30~166*166mm;30~182*182mm;30~182*210mm |

| Cell thickness | ≥160μm |

| Ribbon parameter | |

| Applicable Ribbons

|

Thickness:120μm~250μm;Width:0.6~1.6mm

With lead or without lead |

| Applicable Flux | No-clean flux, without halogen element |

| Stringer parameter | |

| Stringer length | 2000mm/stringer(negotiate if more than it in advance) |

| Bus bar qty | 5、6、9、10、11、12~20BB |

| Distance of cells | 1.0~5.0mm±0.2mm(adjustable) |

| Electric Specification | |

| Peak power | 18kw |

| Average power | 12kw |

| Power | AC380V 50Hz 3phase 5wire |

| Air compressed | ≥0.6Mpa Flow ≥60L/mins |

| Operation Temperature | 23±7℃(recommend) |

Reviews

There are no reviews yet.