Solar Cell Testing&Scribing

Testing and choose qualified solar cell is most important for solar panel production.Solar cell tester is pivotal machine to test designed for the filtration of solar mono-crystalline silicon and poly-crystalline silicon cells.Through the stimulated light irradiation by the solar spectrum lamp-house,the machine classifies the solar cells according to the testing and surveys result with related electrical parameter of solar cells.And then sorting solar cell according to appearance,color,efficiency.

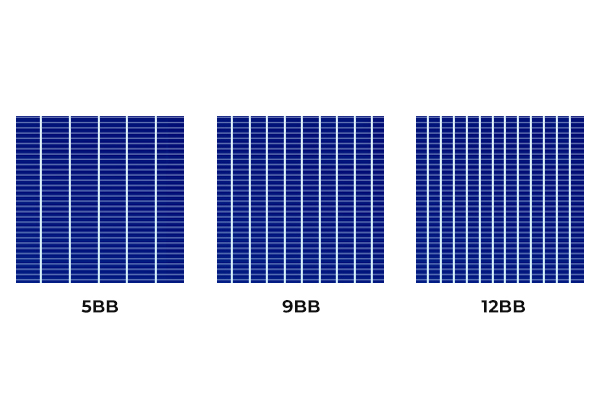

Pv module with Half cutting PERC&TopCon solar cell from 166-210mm 10/16/18BB is popular in the market.Cut whole cell into half pieces by fiber scribing machine automatically,produce big power half cutting solar panel.

Solar cell stringer production&layingUp

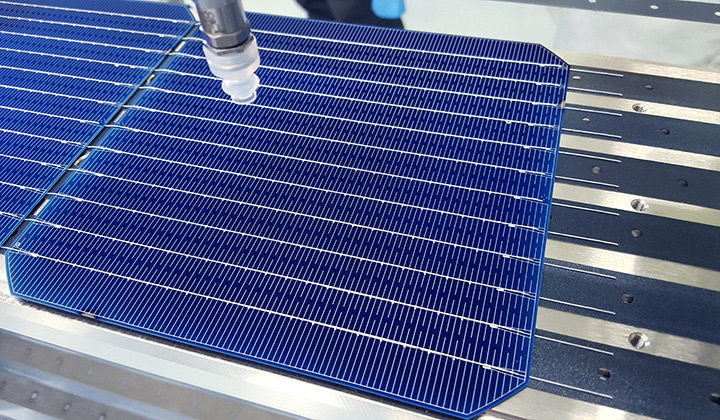

Connect all pieces of half cutting solar cell to be a stringer by tabber&stringer machine,a automatic machine with infrared light for soldering improved quality of solar cell,decreased broken and save material cost.

Tabber&stringer machine has high speed as well as lower speed,lower speed type is using flat ribbon,high speed is compatible with circle ribbon which is better for final pv module efficiency.

Choose proper model for your pv module production!

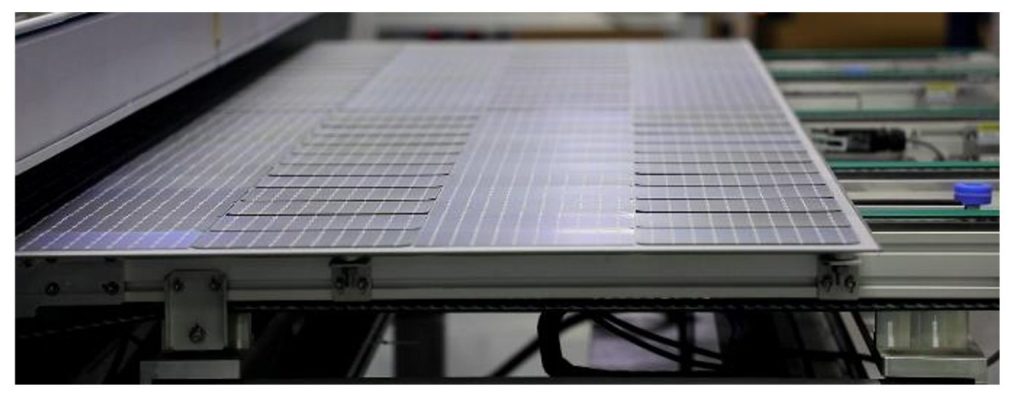

Layup material Eva,solar stringer,Eva,backsheet,solar glass on manual layup station.

Another better choice with less labour is by automatic Robot,It looks marvelous by Robot with not high price.

Layup 2nd EVA,Backsheet and do bussing manually suggested 5-50MW manual line or lower automated level automatic line for pv module production.

Auto bussing is another important machine,improve efficiency with standard&accurate solder,we recommend it from 100MW to 1GW.

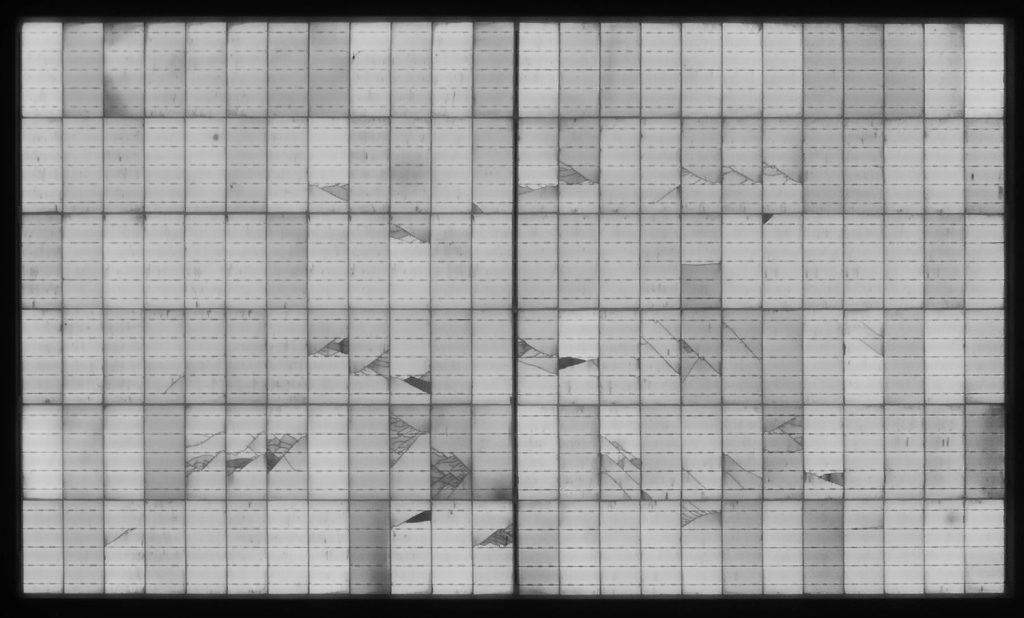

Testing before Lamination

First testing by offline EL tester or Full Automatic EL Defect Tester With Visual Inspecting before lamination.

EL tester comes with 2 or 8 sets of high pixel industrial cameras,get clearer pictures by EL tester,you will find Solder dark spot,Crack spot,Mixed current grade,Solar cell defects,Cold solder,polluted solar cell from solar panel.

Lamination

Laminator encapsulates solar modules by pressing all of the material:solar cell,EVA and back sheet stacked on tempered glass,in a vacuumed and heated condition.